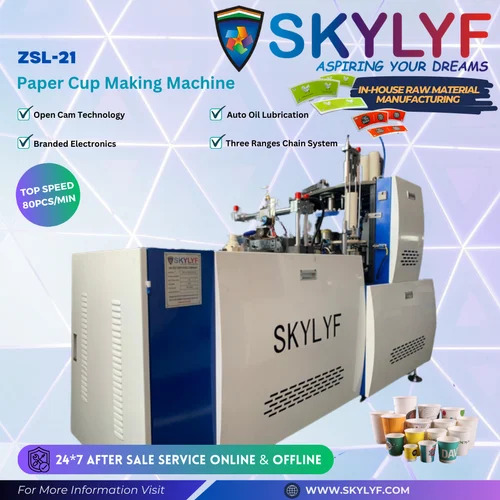

Paper cup making machine manufacturer

Product Details:

- Grade Automatic

- Material MS

- Computerized No

- Control System Human Machine Interface

- Voltage 220-240 Volt (v)

- Warranty 1 Year

- Click to View more

Paper cup making machine manufacturer Price And Quantity

- 650000 INR/Unit

- 1 Unit

Paper cup making machine manufacturer Product Specifications

- Automatic

- MS

- 1 Year

- Human Machine Interface

- No

- 220-240 Volt (v)

Paper cup making machine manufacturer Trade Information

- 10-15 Days

- All India

Product Description

We are the manufacturer of Automatic paper cup making machines which are designed to streamline the process of manufacturing paper cups efficiently. These machines come with various features to enhance productivity, precision, and reliability. While specific features may vary depending on the model and manufacturer, here are some common features you might find in automatic paper cup making machines. Our major market for paper cup making machine inAndhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh.

- High-speed production: Automatic paper cup making machines are capable of producing a large number of cups in a relatively short amount of time, increasing overall efficiency.

- Easy maintenance and troubleshooting: Machines are often designed with accessibility in mind, making it easier for maintenance personnel to access and repair components. They may also include diagnostic features to assist in troubleshooting.

- Fully automated operation: These machines are designed to perform the entire cup-making process automatically, from feeding raw materials to the finished cup collection, minimizing the need for manual intervention.

- Paper feeding system: A reliable paper feeding system ensures a continuous and consistent supply of paper material to the machine, contributing to uninterrupted production.

- Pre-printed paper detection: Some machines come equipped with sensors or systems that can detect pre-printed designs on the paper, ensuring proper alignment and accurate printing of the cups.

- Ultrasonic welding or sealing: Automatic machines often use ultrasonic technology for sealing the paper cups. This method provides a strong and efficient bond between the paper layers without the need for additional adhesives.

- Automatic lubrication system: To ensure smooth and trouble-free operation, some machines include automatic lubrication systems to reduce wear and tear on moving parts.

- Touchscreen control panel: An intuitive touchscreen interface allows operators to easily set parameters, monitor the production process, and make adjustments as needed.

- Multi-station design: Many machines have multiple stations or steps in the production line, each dedicated to a specific task, such as cup forming, bottom punching, and curling.

- Quality control mechanisms: Integrated sensors and systems can monitor the quality of the produced cups, identifying defects and ensuring that only high-quality cups are delivered.

- Energy-efficient design: Some machines are designed with energy-saving features to reduce overall power consumption, contributing to cost savings and environmental sustainability.

- Easy maintenance and troubleshooting: Machines are often designed with accessibility in mind, making it easier for maintenance personnel to access and repair components. They may also include diagnostic features to assist in troubleshooting.

FAQs of Paper cup making machine manufacturer:

Q: What is the voltage requirement for the Paper cup making machine?

A: The voltage requirement for the Paper Cup making machine is 220-240 Volt (v).Q: What type of control system does the machine have?

A: The machine has a Human Machine Interface control system.Q: Is the machine computerized?

A: No, the machine is not computerized.Q: What is the warranty period for the machine?

A: The machine comes with a 1 year warranty.Q: What is the material used in the construction of the machine?

A: The machine is made of MS (Mild Steel).Q: What is the grade of the machine?

A: The machine is of Automatic grade.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+